Forged vs cast irons: forged pieces are stronger and tougher, while cast irons are dense, stable, and often cheaper.

I have worked with metal tools and cookware for years. I will walk you through forged vs cast irons with clear facts and hands-on tips. Expect practical comparisons, real-world examples, and buying and care advice you can use today. Read on to learn which option fits your needs.

Quick technical overview: forged vs cast irons

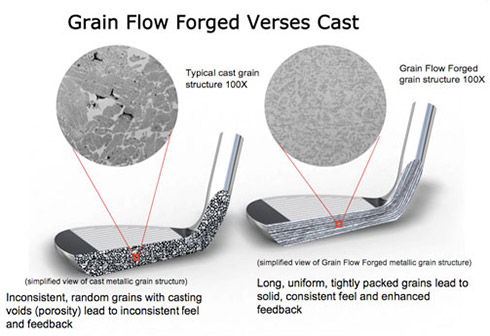

Forging shapes metal by hammering or pressing. Casting pours molten metal into a mold. These simple differences create big changes in strength, grain, and use. In short, forged vs cast irons means different structure and different uses.

Forged parts usually have aligned grain and fewer internal voids. Cast irons can have complex shapes and internal graphite that change how they behave. When you compare forged vs cast irons, think strength, toughness, and shape limits.

How they are made: process and material

Forged parts begin with solid metal heated and shaped under high pressure. The process refines the metal's internal grain. This makes forged pieces dense and tough.

Cast irons use molten iron poured into a mold. The metal cools and forms shapes that forging can’t easily make. Casting allows complex parts and lower cost per shape. The choice between forged vs cast irons often comes down to production needs and budget.

Mechanical properties and performance

Forged parts resist shock and bending well. They have better impact resistance and tensile strength. That is why many load-bearing tools are forged.

Cast irons are stiff and stable under compression. They handle wear and high heat with ease but can be brittle under sharp impacts. For uses needing hardness and shape complexity, cast irons win. When you weigh forged vs cast irons, match the property to the job.

Common applications: tools, cookware, and machine parts

Forged items include wrenches, connecting rods, and some knives. These items need toughness and a strong grain flow. Forged parts also get fine surface finish after shaping.

Cast irons appear as engine blocks, cookware skillets, and machine bases. They offer good wear resistance and quiet damping. In kitchens, cast iron pans hold heat well. When choosing between forged vs cast irons, consider load patterns and shape needs.

Cooking use: forged vs cast irons in the kitchen

Cast iron cookware is common in home kitchens for searing and even heating. It holds heat and adds stable surface contact. Many cooks prefer cast irons for their heat retention.

Forged cookware is rarer. Some high-end pans are forged from steel for quick heat response and thinner walls. If you want fast response at the stove, forged pans may suit you better. Think forged vs cast irons in terms of heat hold vs heat response.

Durability, maintenance, and repair

Forged pieces can bend but rarely crack; they can often be straightened and repaired. Their grain structure helps resist fracture. This makes forged parts long-lived in demanding use.

Cast irons resist wear and hold shape well but can crack if dropped or struck sharply. Small cracks are hard to repair. Both need rust protection; seasoning helps cast iron cookware. Compare forged vs cast irons for repairability and care.

Cost, manufacturing scale, and lead time

Forging needs heavy dies and high force. That raises initial cost for small runs. Forged parts are cost-effective for many repeated parts when strength matters.

Casting scales well for complex shapes and large runs. Molds add cost but allow faster per-part production. Cast parts can be cheaper for mass production. When deciding forged vs cast irons, factor in quantity, tooling cost, and time.

Personal experience and practical tips

I once swapped a forged crank arm for a cast one in a project. The cast arm fit well but chipped after repeated sharp impacts. The forged arm later survived heavy use with only minor reshaping. That taught me to match forged vs cast irons to the stress type.

When buying, inspect for surface voids on cast items. For forged goods, check for uniform grain and no sharp cracks. For cookware, I season cast iron and polish forged steel lightly. These small steps extend life and performance.

Buying guide: choose for the job

Ask these questions before you buy:

- What load will the part carry? Forged is best for impact and tension.

- Do you need complex shapes or thin walls? Cast is often better for shape freedom.

- What is your budget and run size? Cast suits large runs; forged suits strength needs.

- How will you maintain the item? Cast iron cookware needs seasoning; forged steel may need rust control.

- Do you value repairability? Forged parts are usually easier to repair.

Match the choice of forged vs cast irons to the answers above. This makes your purchase clear and smart.

Environmental and safety notes

Forging uses high energy for heating and pressing but produces dense parts with low scrap in many setups. Casting can generate fumes and demands good mold handling. Recycling scrap metal reduces overall impact for both methods. When weighing forged vs cast irons, also consider production footprint and worker safety.

Frequently Asked Questions of forged vs cast irons

What is the main difference between forged vs cast irons?

The main difference is process: forging shapes solid metal under pressure, while casting pours molten metal into molds. This leads to stronger grain in forged parts and more complex shapes in cast parts.

Is forged iron always stronger than cast iron?

Forged iron is generally tougher and better at resisting impact and fatigue. Cast iron can be harder and stable under compression but is more brittle in shock situations.

Which is better for cookware: forged vs cast irons?

Cast iron cookware holds heat longer and is common for searing. Forged steel pans heat faster and respond quicker; both have pros depending on cooking style.

Can cast iron be repaired if it cracks?

Small cracks in cast iron are difficult to repair and often require specialist welding. Forged parts are usually easier to reshape or weld.

How do costs compare for forged vs cast irons?

Forging has higher tooling and setup costs but is cost-effective for strong parts in smaller runs. Casting scales well for complex shapes and high volumes, often lowering per-part cost.

Are forged parts safer for high-stress machine applications?

Yes. Forged parts are preferred in high-stress applications because they resist fatigue and shock better than cast parts. This improves safety and service life.

Conclusion

Forged vs cast irons is a choice of process, performance, and price. Forged parts win for toughness, repairability, and impact resistance. Cast irons win for shape complexity, heat retention, and cost at scale. Use the guide above to match the metal to your need, whether for tools, engines, or cookware.

Take action now: inspect the part, list the stresses it will face, and pick the method that fits that list. If you found this useful, leave a comment, try a small test part, or subscribe for more hands-on metal and product advice.