Wedge types explained: simple distinctions across golf, woodworking, and mechanical wedges.

As a longtime craftsman and weekend golfer, I’ll walk you through wedge types explained with clear, practical detail you can use today. This guide breaks down what a wedge is, why different wedge types matter, and how to pick and use the right wedge for golf, carpentry, and mechanical work. Read on for easy comparisons, real-world tips from my own toolbox and bag, and actionable advice to help you choose with confidence.

What is a wedge? Basic definition and everyday uses

A wedge is a simple tool and mechanical principle: a triangular or tapered shape that converts force into separating or lifting action. Wedges appear as tools, fasteners, and parts in many fields, including golf, woodworking, and machinery. Understanding wedge types explained helps you match a wedge’s shape, material, and angle to the task at hand.

Wedges can split, lift, hold, or redirect force. Their effectiveness comes from geometry and material, not complexity.

Common wedge types and where they're used

Below are the main wedge families you’ll encounter. For each, I explain core traits and typical uses so the phrase wedge types explained becomes a practical checklist rather than jargon.

Mechanical and utility wedges

- Knife-edge wedges used to split material or hold parts apart in repair work.

- Door or rubber wedges used to hold doors open or for blocking in construction.

- Shims (thin wedge-shaped pieces) used to level and align components.

Woodworking wedges and shims

- Wooden wedges used to separate glued joints or drive tenons.

- Plastic or composite shims used for window and door installation.

- Metal splitting wedges used with a hammer to split logs.

Fastening and connector wedges

- Wedge anchors used in masonry to secure bolts in concrete.

- Tapered key wedges used in machine shafts to lock pulleys or gears.

Golf wedges

- Pitching wedge — higher loft for approach shots and controlled trajectory.

- Gap wedge — fills loft gap between pitching and sand wedges.

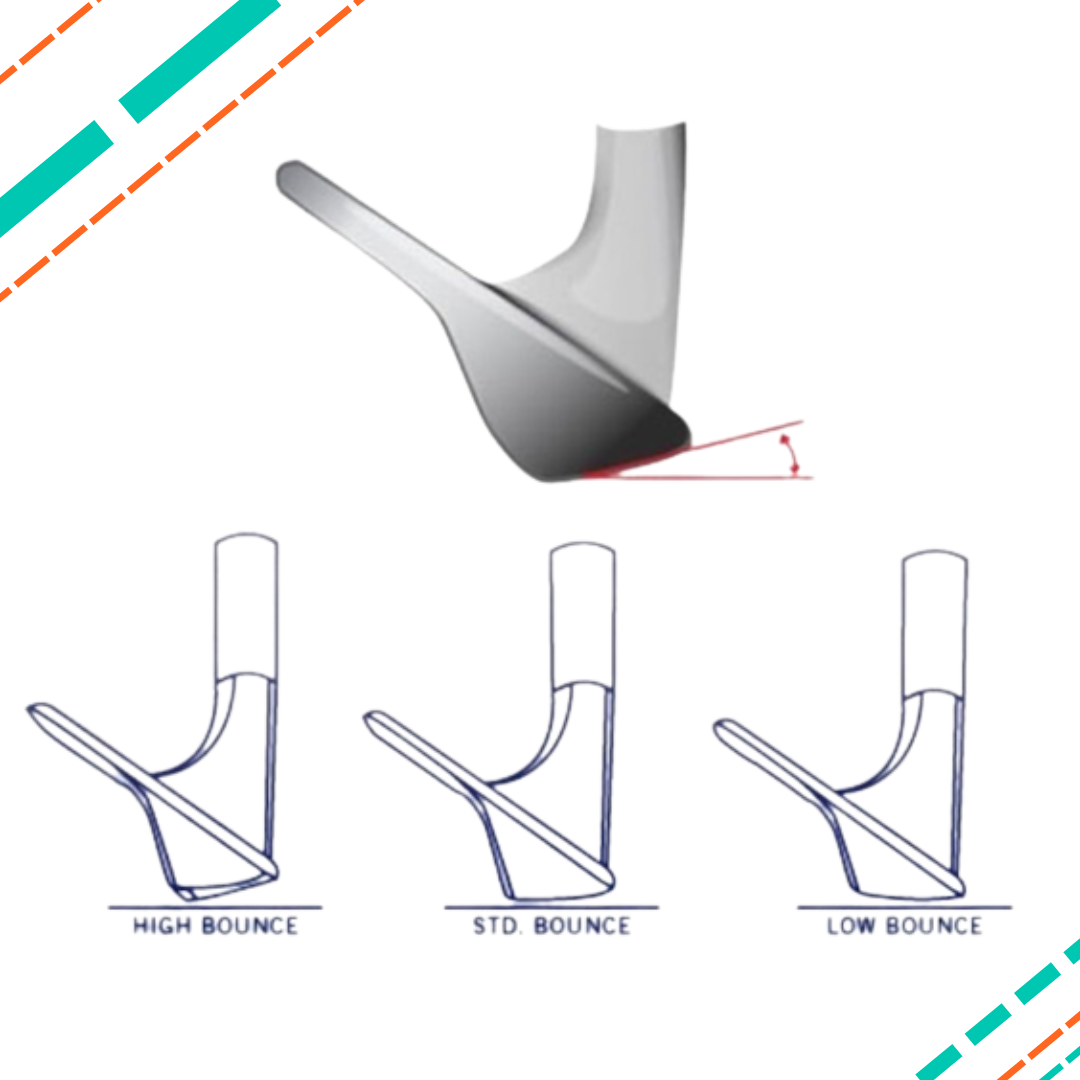

- Sand wedge — designed for bunker play with higher bounce.

- Lob wedge — very high loft for short, high shots around the green.

Knowing wedge types explained across these categories helps you pick the right angle, material, and finish for the job.

How to choose the right wedge for the job

Choose by purpose, geometry, and material. Keep decisions simple and task-focused.

- Define the task — Are you splitting wood, stopping a door, anchoring something in concrete, or hitting a short golf shot?

- Match the geometry — For splitting, use a thin, sharp wedge; for holding, use a blunt or rubber wedge. For golf, choose loft and bounce to match turf and swing speed.

- Consider material — Hardened steel for heavy duty, wood or plastic for gentle work, carbon or forged steel for golf depending on feel.

- Test fit or try in store — For tools and golf clubs, hands-on testing prevents surprises.

From my workshop: when installing a door, using a set of plastic shims reduced gap problems and saved time. In golf, switching a wedge with a different bounce cured frequent fat shots. These choices come from observing how wedge types explained behave under real conditions.

How to use, maintain, and store wedges

Proper use and care extends wedge life and performance. Follow simple habits.

- Use the right strike and support — Drive metal wedges with a mallet or hammer on a metal striker, not a soft hammer.

- Keep edges sharp for splitting; for golf, keep grooves clean for spin.

- Inspect for cracks and wear — Replace worn wedges used in heavy splitting or construction.

- Store dry and secure — Prevent rust on metal wedges and warping on wooden wedges.

A tip from my toolbox: label shims and wedges by thickness. That small step avoids trial-and-error and keeps work fast and accurate.

Materials, design, and manufacturing differences

Different materials and manufacturing processes create very different wedges. Understand the options.

- Forged steel — common for durable, high-feel golf wedges and heavy-duty splitting tools.

- Cast steel or stainless — used where cost and corrosion resistance matter.

- Wood and plastic — used for shims and lighter household wedges.

- Surface finishes — coatings reduce rust and change friction; in golf, finishes affect glare and feel.

Design features matter too. In golf, bounce, grind, and loft determine turf interaction. In tools, taper angle and edge radius control splitting force and safety. Choosing among wedge types explained means knowing these material and design trade-offs.

Common mistakes and how to avoid them

Avoid these frequent errors I’ve seen from beginners and pros alike.

- Picking by price alone — Cheap wedges often fail sooner or perform poorly. Invest in the right type for the job.

- Ignoring geometry — Using a splitting wedge for prying or a low-bounce golf wedge in sand leads to bad outcomes.

- Poor maintenance — Rusted or dull wedges reduce control and increase risk.

- One-size-fits-all thinking — Different tasks need different wedge features; treat each task individually.

When I first started woodworking, I used a single wedge for too many tasks and paid with lost time and damaged pieces. Matching wedge types explained to the job saved my work and patience.

:max_bytes(150000):strip_icc()/meet-the-golf-clubs-1560507_FINAL1-96bcd811ce0d4863a05afca4096478c9.png)

Personal experience: lessons from the shop and the course

I’ve used many wedges over 20 years — from splitting logs to dialing in short golf shots. Here are practical lessons that work.

- Carry a small kit — a set of plastic shims, a steel pinch wedge, and a rubber door wedge solves most on-site problems.

- For golf, experiment with one wedge change at a time. Track shots over a few rounds before deciding.

- Label and store wedges by use. It saves time and reduces mistakes.

- Respect safety — wedges concentrate force. Wear eye protection and use a stable surface when splitting.

These insights come from trial, occasional errors, and steady improvements. They reflect how wedge types explained translate into smoother projects and better scores.

Frequently Asked Questions of wedge types explained

What is the main difference between a wedge and a shim?

A wedge has a taper and is often used to split or hold under force, while a shim is typically thin for leveling and small adjustments. Both are wedge-shaped but differ in thickness and intended function.

How do I choose the right golf wedge for short shots?

Choose based on loft and bounce. Higher lofts and more bounce help with soft turf and sand, while lower bounce works better on tight lies.

Can the same wedge be used across trades?

Some wedges are versatile, like rubber door wedges or simple shims, but most are optimized for a specific trade and task. Use dedicated wedges for safety and best results.

How often should I replace a metal wedge used for splitting?

Replace when the edge becomes rounded, cracked, or the wedge shows significant deformation. Frequent heavy use can mean replacement every few years.

What maintenance keeps golf wedges performing well?

Keep grooves clean, check for wear, and regrind only when done by a professional. Clean after each round to maintain spin and consistency.

Conclusion

Wedge types explained matter because small geometry and material choices make big differences in safety, accuracy, and performance. Match the wedge to the task, care for it, and test changes gradually. Takeaway: be intentional — pick the right wedge, try it, and keep it maintained to get reliable results. Ready to put this into practice? Try organizing a small wedge kit for one project or swap a single golf wedge and track the change, then share what you learn in the comments.